Wrought aluminum alloys are engineered through mechanical working processes (rolling, extrusion, forging) to achieve superior strength, ductility, and corrosion resistance compared to cast alloys. These alloys are classified by 4-digit series based on primary alloying elements, enabling tailored solutions for aerospace, automotive, and industrial applications.

Wrought aluminum alloys are engineered metallic materials renowned for their exceptional strength-to-weight ratio, corrosion resistance, and formability, achieved through strategic alloying with elements like copper, magnesium, silicon, and zinc to tailor mechanical, thermal, and electrical properties. These alloys—categorized into series such as 1xxx (high-purity), 2xxx (aerospace-grade), 5xxx (marine-resistant), 6xxx (architectural/automotive), and 7xxx (ultra-high-strength)—excel in applications demanding lightweight durability, including aircraft structures, automotive frames, marine components, and architectural extrusions. Their adaptability to processes like extrusion, rolling, and forging, combined with advanced tempers, ensures optimized performance under extreme conditions.

Overview of Wrought Aluminum

Wrought aluminum alloys are engineered through strategic alloying to balance strength, ductility, corrosion resistance, and workability. The Aluminum Association (AA) categorizes them into four principal series:

Microalloying Innovations:

- Zr (Zirconium): Forms Al₃Zr dispersoids to refine grain structure (e.g., 7055-T7751 alloy for Boeing 787 wing ribs).

- Sc (Scandium): 0.1–0.3% Sc increases recrystallization resistance by 300%, enabling 7xxx alloys to retain strength at 300°C (critical for hypersonic vehicles).

Chemical Composition & Alloy Series

| Series | Primary Alloying Element | Key Grades | Typical Composition |

|---|---|---|---|

| 1xxx | ≥99% Aluminum (Pure Al) | 1050, 1100, 1199 | Al-Fe-Si (Fe <1%) |

| 2xxx | Copper (Cu) | 2024, 2014, 2219 | Al-Cu-Mg (Cu 2-6%) |

| 3xxx | Manganese (Mn) | 3003, 3004, 3105 | Al-Mn-Fe (Mn 0.5-1.5%) |

| 5xxx | Magnesium (Mg) | 5052, 5083, 5754 | Al-Mg (Mg 0.5-6%) |

| 6xxx | Magnesium + Silicon (Mg-Si) | 6061, 6063, 6082 | Al-Mg-Si (Mg 0.5-1.5%, Si 0.4-1.3%) |

| 7xxx | Zinc (Zn) | 7075, 7050, 7049 | Al-Zn-Mg-Cu (Zn 4-8%) |

Physical & Mechanical Properties

| Property | 1xxx | 3xxx | 5xxx | 6xxx | 7xxx |

|---|---|---|---|---|---|

| Density (g/cm³) | 2.70 | 2.73 | 2.68 | 2.70 | 2.81 |

| Melting Range (°C) | 640-660 | 630-655 | 580-640 | 580-650 | 475-635 |

| Thermal Conductivity (W/m·K) | 220 | 160 | 130 | 170 | 120 |

| Electrical Conductivity (%IACS) | 59-64 | 40-50 | 30-40 | 45-55 | 30-40 |

| Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HV) |

|---|---|---|---|---|

| 1050-O | 70 | 30 | 35+ | 20 |

| 3003-H14 | 150 | 145 | 8 | 40 |

| 5052-H32 | 230 | 195 | 12 | 60 |

| 6061-T6 | 310 | 275 | 12 | 95 |

| 7075-T6 | 570 | 505 | 11 | 175 |

Key Advantages of Wrought Aluminum Alloys

With a focus on sustainability—offering 95% recyclability and lower embodied carbon than steel—wrought aluminum alloys remain pivotal in industries prioritizing energy efficiency, material longevity, and design flexibility, making them indispensable for modern engineering challenges.

✔ High Strength-to-Weight Ratio – 7xxx alloys exceed 500 MPa tensile strength (comparable to steel at 1/3 the weight).

✔ Corrosion Resistance – 5xxx alloys offer saltwater immunity; 6xxx alloys resist atmospheric corrosion.

✔ Formability – 1xxx/3xxx grades allow 90%+ cold reduction for deep drawing.

✔ Weldability – 5xxx/6xxx alloys are easily welded (TIG, MIG, FSW).

✔ Recyclability – Requires only 5% of the energy needed for primary production.

Manufacturing Processes & Cost Considerations

A. Production Methods

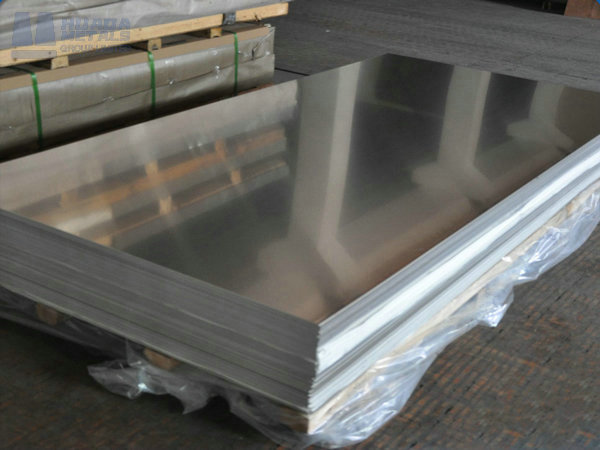

Hot Rolling (>300°C): For plates/sheets (1xxx-7xxx).

Cold Rolling: Improves surface finish & strength (H temper series).

Extrusion: Complex profiles (6xxx alloys dominate).

Forging: High-strength aerospace parts (2xxx/7xxx).

B. Cost Factors

| Alloy Series | Relative Cost | Primary Cost Driver |

|---|---|---|

| 1xxx/3xxx | $ | Low alloy content |

| 5xxx/6xxx | $$ | Mg/Si additions |

| 2xxx/7xxx | $$$ | Cu/Zn + heat treatment |

Industry Applications of Wrought Aluminum

Aerospace & Defense

- 2024-T351: Wing skins in F-16 fighters (strength-to-weight ratio: 190 kN·m/kg).

- 7050-T7451: Fuselage frames in Airbus A350 (fatigue life: 50,000 flight cycles).

Automotive

- 6016-T4: Body-in-white panels for BMW i3 (crash energy absorption: 120 kJ/m² at 56 km/h).

- 5754-H22: Electric vehicle battery trays (corrosion current density: 0.1 μA/cm² in electrolyte).

Construction & Infrastructure

- 6063-T5: Architectural extrusions for Burj Khalifa (U-value: 1.2 W/m²K with thermal breaks).

- 5086-H116: Offshore platform decks (seawater resistance: 10-year design life).

Aerospace & Defense

2xxx (2024): Aircraft skins, wing structures.

7xxx (7075): Landing gear, missile components.

Automotive

5xxx (5182): Fuel tanks, body panels.

6xxx (6061): Chassis, bumper beams.

Construction

6xxx (6063): Window frames, curtain walls.

5xxx (5083): Bridges, marine structures.

Consumer Electronics

1xxx (1050): Capacitor foils, heat sinks.

Quality Standards & Certifications

ASTM B209/B221: Sheet/extrusion standards.

AMS 4000-series: Aerospace material specs.

ISO 6361: International wrought alloy designations.

Cost Breakdown (6061-T6 Extrusion)

| Component | Cost Contribution (%) | Optimization Levers |

|---|---|---|

| Raw Material | 55–65 | Use of recycled scrap (e.g., UBCs) reduces input cost by 20%. |

| Energy | 15–20 | Hydroelectric-powered smelters (e.g., Norway’s Hydro Alunorte) cut costs by 30%. |

| Processing | 10–15 | Additive manufacturing of complex dies reduces lead times by 50%. |

| Finishing | 5–10 | Anodizing vs. painting trade-offs (anodizing adds $0.8/kg but eliminates VOC emissions). |

In Conclusion

Wrought aluminum alloys represent the pinnacle of metallurgical innovation, offering tunable performance across industries demanding lightweighting, durability, and sustainability. From hypersonic flight to renewable energy infrastructure, these materials continue to evolve through advanced alloy design, precision processing, and circular manufacturing practices. For engineers seeking to push the boundaries of material science, wrought aluminum alloys remain an indispensable toolkit. Welcome to inquiry and ask for the lastest price, please contact us.

Future Directions

- Additive Manufacturing:

- Wire-arc AM of 2319 alloy enables 100% dense aerospace brackets with 30% buy-to-fly ratio improvements.

- Friction Stir Welding (FSW):

- Joins 7075-T6 without fusion zone defects, critical for SpaceX Starship interstage rings.

- AI-Driven Alloy Design:

- Citrine Informatics’ platform predicts 7xxx alloy compositions with 20% higher SCC resistance using machine learning.