Ultra-low carbon steels (ULCS) refers to steels with carbon content typically below 0.05%, engineered to optimize formability, weldability, and corrosion resistance. This steel category includes IF (Interstitial-Free) steel, ultra-low carbon bainitic steel (ULCB), and high-purity ferritic stainless steel, tailored for industries demanding stringent mechanical properties and processability.

Overview of Ultra-low Carbon Steel

Ultra-low carbon steel (ULCS) is a specialized ferrous alloy containing less than 0.03% carbon, offering exceptional formability, weldability, and corrosion resistance. These steels are particularly valuable in applications requiring deep drawing, excellent surface quality, and resistance to intergranular corrosion.

Chemical Composition of Ultra-low Carbon Steel

| Grade | Carbon (C) % | Manganese (Mn) % | Silicon (Si) % | Titanium (Ti) / Niobium (Nb) % | Chromium (Cr) % | Nickel (Ni) % | Molybdenum (Mo) % |

|---|---|---|---|---|---|---|---|

| IF Steel (e.g., Ti-IF) | ≤0.008 | 0.10–0.30 | ≤0.05 | Ti: 0.05–0.15 | — | — | — |

| ULCB Steel | ≤0.05 | 1.5–2.0 | ≤0.25 | — | — | — | B: 0.001–0.003, Mo: 0.2–0.5 |

| High-Purity Ferritic Stainless Steel (e.g., 430Ti) | ≤0.02 | ≤1.00 | ≤1.00 | Ti: 0.10–0.30 | 16.0–18.0 | — | — |

Key Notes:

- IF Steel: Ultra-low carbon (<0.008%) with Ti/Nb additions to fix interstitial atoms (C, N), enhancing formability.

- ULCB Steel: Mn and B promote bainite formation; Mo refines grain structure.

- Ferritic Stainless Steel: High Cr content improves corrosion resistance; Ti stabilizes the ferrite phase.

Physical & Mechanical Properties of Ultra-low Carbon Steel

| Property | IF Steel | ULCB Steel | Ferritic Stainless Steel (430Ti) |

|---|---|---|---|

| Hardness (HRC) | 50–60 (annealed) | 40–50 (as-rolled) | 180–220 HB (Brinell) |

| Tensile Strength (MPa) | 270–350 | 600–800 | 450–600 |

| Yield Strength (MPa) | 140–240 | 500–700 | 205–310 |

| Elongation (%) | 38–45 | 18–25 | 22–28 |

| Density (g/cm³) | 7.85 | 7.85 | 7.70 |

| Thermal Conductivity (W/m·K) | 45–55 | 35–45 | 26–30 |

Key Notes:

- IF Steel: Exceptional ductility (elongation >38%) and low yield strength enable deep drawing.

- ULCB Steel: High strength-to-weight ratio (~800 MPa tensile strength) with excellent toughness (Charpy impact >100 J at -40°C).

- Ferritic Stainless Steel: Superior corrosion resistance (passivation layer) but lower ductility than IF steel.

Key Advantages of Ultra-low Carbon Steel

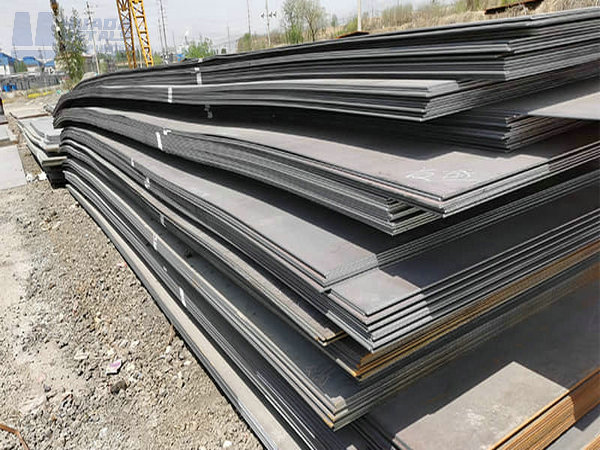

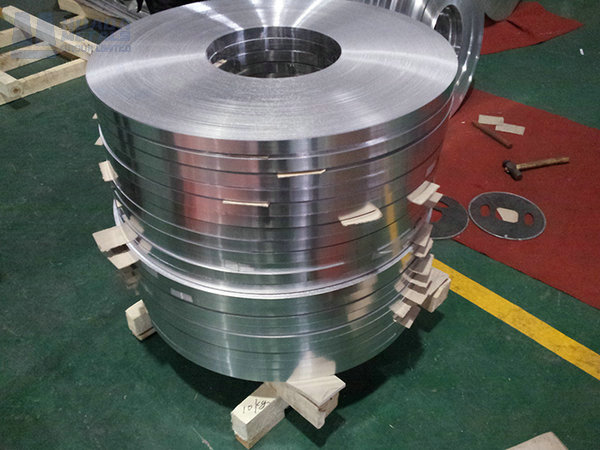

HuaDa Metals has the various shape of the carbon steel content: 0.25%-0.60% Properties: Increased strength and hardness, decreased ductility and toughness, preheating for welding. Applications: Gears, shaft parts, machine tool guides. Examples: 45 steel (carbon content 0.42%-0.50).

✔ Exceptional formability (deep drawing, stretch forming)

✔ Superior weldability (no martensite formation)

✔ Excellent surface quality (for coating/painting)

✔ Resistance to aging and intergranular corrosion

✔ Consistent mechanical properties

✔ Good machinability in annealed condition

Manufacturing Processes of Ultra-low Carbon Steel

- Raw Material Cost:

- IF Steel: ~700–900/ton (cheaper than HSLA steels).

- ULCB Steel: 1,200–1,800/ton (due to Mo, B additions).

- Ferritic Stainless Steel: 1,500–2,200/ton (Cr, Ti content).

- Processing Cost:

- Cold Rolling: +200–400/ton (for IF steel).

- Controlled Rolling (ULCB): +300–500/ton (for fine grain structure).

- Annealing (Ferritic SS): +150–300/ton (stress relief).

- Total Cost:

- IF Steel: 900–1,300/ton.

- ULCB Steel: 1,500–2,300/ton.

- Ferritic Stainless Steel: 1,650–2,500/ton.

Applications of Ultra-low Carbon Steel

| Industry | Components | Key Requirements |

|---|---|---|

| Automotive | Body panels, chassis, fuel tanks | High formability, corrosion resistance, lightweight |

| Oil & Gas | Pipelines (X70/X80), offshore platforms | High toughness, weldability, H₂S resistance |

| Construction | Roofing, cladding, architectural panels | Aesthetic finish, weather resistance |

| Appliances | Washing machine drums, refrigerator liners | Corrosion resistance, deep drawability |

| Aerospace | Engine casings, structural brackets | Lightweight, fatigue resistance |

| Material | Base Cost | Processing Cost | Total Cost |

|---|---|---|---|

| A620 | $600-800 | $200-300 | $800-1100 |

| A621 | $650-850 | $250-350 | $900-1200 |

| DC04 | $700-900 | $300-400 | $1000-1300 |

| IF Steel | $750-1000 | $350-450 | $1100-1450 |

| Mild Steel (0.1%C) | $500-700 | $150-250 | $650-950 |

In Conclusion

Ultra-low carbon steels represent a paradigm shift in material engineering, balancing formability, strength, and corrosion resistance at competitive costs.

- IF Steel dominates automotive and appliance sectors for its unmatched deep-drawing capabilities.

- ULCB Steel is the backbone of oil & gas infrastructure, offering weldability and toughness unmatched by conventional steels.

- Ferritic Stainless Steel provides a cost-effective alternative to austenitic grades in moderately corrosive environments.

HuaDa Metals has the good quality products in medium carbon steel, and the service is customerized for every clients, please contact us or ask for the lastest price. For industries requiring complex formed parts with high surface quality – particularly automotive, appliance, and packaging sectors – ultra-low carbon steels remain the material of choice. Continued advancements in IF steel technology and processing methods promise even better performance in future applications.