An alloy is a material made by combining two or more metallic elements (or a metal with non-metallic elements) to enhance specific properties such as strength, corrosion resistance, hardness, or electrical/thermal conductivity. Unlike pure metals, which have limited industrial applications due to their inherent weaknesses, alloys are engineered to meet precise performance requirements.

An alloy is a homogeneous mixture of two or more metals, or a metal combined with one or more non-metallic elements (e.g., carbon, silicon), engineered to enhance specific properties beyond what pure metals can achieve. Alloys are not chemical compounds (where elements bond at a molecular level) but rather solid solutions or intermetallic mixtures where atoms are randomly distributed or arranged in ordered phases.

Overview of Alloy

An alloy is a metallic material composed of two or more elements, where at least one is a metal. By combining different elements, alloys achieve enhanced properties compared to pure metals, such as increased strength (steel), corrosion resistance (stainless steel), or lightweight durability (aluminum alloys). Common alloying techniques include mixing molten metals or diffusion bonding. Alloys are fundamental in industries like construction (carbon steel), aerospace (titanium alloys), and electronics (solders). Their customizable nature allows engineers to optimize hardness, conductivity, and melting points for specific applications. Examples include brass (copper+zinc) and bronze (copper+tin). Alloys revolutionized modern technology by overcoming the limitations of pure metals.

Ferrous Alloys (Iron-Based)

| Alloy | Composition | Key Properties | Applications |

|---|---|---|---|

| Carbon Steel | Fe + 0.05–2.1% C | Strength increases with carbon content; hardenable. | Tools, machinery, structural beams. |

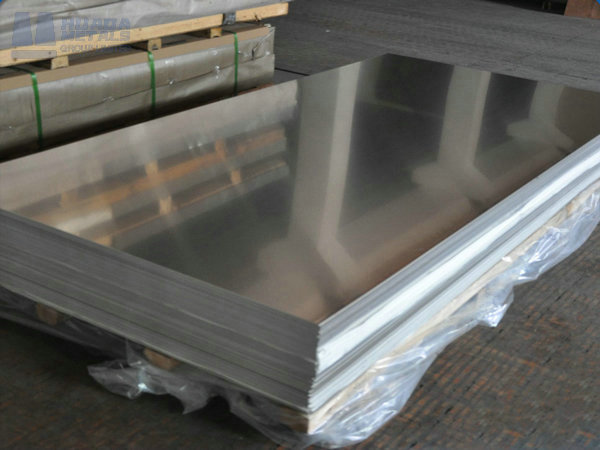

| Stainless Steel | Fe + 10.5–30% Cr (+Ni, Mo, N) | Corrosion-resistant, hygienic, aesthetic. | Kitchenware, medical implants, architectural cladding. |

| Tool Steel | Fe + 0.7–1.5% C + Cr, V, W, Mo | Extremely hard, wear-resistant. | Cutting tools, dies, molds. |

Non-Ferrous Alloys (Non-Iron-Based)

| Alloy | Composition | Key Properties | Applications |

|---|---|---|---|

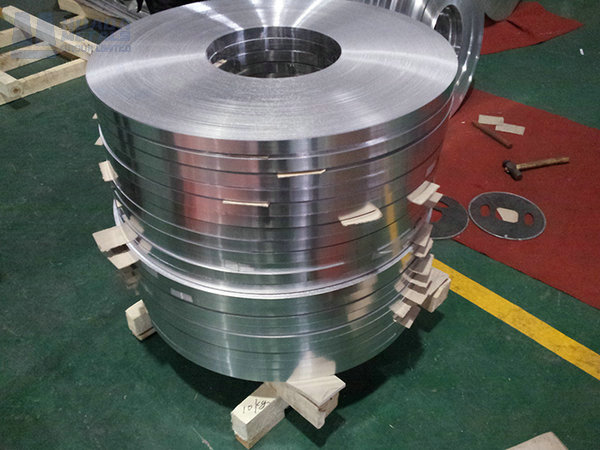

| Aluminum Alloys | Al + Cu, Mg, Zn, Si, Mn, Li | Lightweight, strong, corrosion-resistant. | Aircraft frames, automotive panels, beverage cans. |

| Bronze | Cu + Sn (+Zn, Pb, P) | High strength, low friction, anti-galling. | Bearings, marine propellers, sculptures. |

| Titanium Alloys | Ti + Al, V, Mo, Nb | High strength-to-weight ratio, biocompatible. | Aerospace engines, medical implants, sports gear. |

| Nickel Superalloys | Ni + Cr, Co, Mo, W, Re, Ta | Exceptional high-temperature strength, creep resistance. | Jet engines, gas turbines, rocket components. |

How Alloys Are Made

- Melting & Casting:

- Base metal and alloying elements are melted in a furnace (e.g., induction, electric arc).

- Molten alloy is cast into ingots, billets, or directly into shapes (e.g., die-casting).

- Powder Metallurgy:

- Fine metal powders are mixed, compacted, and sintered (heated below melting point).

- Used for tungsten carbide tools or titanium implants with controlled porosity.

- Additive Manufacturing (3D Printing):

- Metal alloys (e.g., Ti-6Al-4V, AlSi10Mg) are fused layer-by-layer using lasers or electron beams.

- Enables complex geometries and reduced material waste.

| Grade | Carbon (C, wt%) | Chromium (Cr, wt%) | Nickel (Ni, wt%) | Molybdenum (Mo, wt%) | Key Applications |

|---|---|---|---|---|---|

| 4130 | 0.28–0.33 | 0.80–1.10 | 0.40–0.60 | 0.15–0.25 | Aircraft frames, gears |

| 4140 | 0.38–0.43 | 0.80–1.10 | 0.15–0.35 | 0.15–0.25 | Axles, drill collars |

| 4340 | 0.38–0.43 | 1.65–2.00 | 1.65–2.00 | 0.20–0.30 | Landing gear, shafts |

| 304 Stainless (Special Case) | ≤0.08 | 18.0–20.0 | 8.0–11.0 | N/A | Food processing, medical devices |

Key Characteristics of Alloys

Enhanced Mechanical Properties

Alloys are stronger and harder than pure metals.

Example: Steel (Fe + C) is stronger than pure iron.

Improved Corrosion Resistance

Some alloys resist rust and chemical degradation better than pure metals.

Example: Stainless steel (Fe + Cr + Ni) resists oxidation.

Tailored Electrical & Thermal Conductivity

Alloys can be optimized for specific conductivity needs.

Example: Brass (Cu + Zn) is more durable than pure copper.

Better Workability & Formability

Some alloys are easier to cast, weld, or machine.

Example: Aluminum alloys (Al + Mg/Si) are widely used in aerospace.

Controlled Melting Points

Alloys often have lower melting points than pure metals.

Example: Solder (Pb + Sn) melts at a lower temperature than pure lead.

| Property | Pure Metal Limitation | Alloy Solution |

|---|---|---|

| Strength | Pure aluminum is too soft for structural use. | Aluminum-zinc (7075 alloy): 500+ MPa yield strength (vs. pure Al’s 10 MPa). |

| Corrosion Resistance | Iron rusts rapidly in moist air. | Stainless steel (Fe + 18% Cr + 8% Ni): Forms a passive oxide layer, preventing rust. |

| Melting Point | Pure tin is too soft for soldering. | Solder alloy (Sn + Pb/Ag/Cu): Lowers melting point to 180–220°C (vs. tin’s 232°C). |

| Electrical Conductivity | Copper is expensive for large-scale wiring. | Copper-clad aluminum (CCA): Reduces cost while maintaining 60% of copper’s conductivity. |

| Thermal Expansion | Pure aluminum expands excessively when heated. | Invar (Fe + 36% Ni): Ultra-low thermal expansion coefficient (1.2 ppm/°C). |

Future of Alloys: Innovations & Sustainability

- High-Entropy Alloys (HEAs):

- Mixtures of 5+ elements in near-equal proportions (e.g., CoCrFeMnNi).

- Exceptional strength, corrosion resistance, and radiation tolerance (for nuclear reactors).

- Biodegradable Alloys:

- Mg-Ca-Zn alloys dissolve harmlessly in the body, replacing permanent implants.

- Low-Carbon Alloys:

- Hydrogen-reduced iron alloys and recycled-content aluminum reduce CO₂ emissions.

- Smart Alloys:

- Shape-memory alloys (NiTi) return to original shape when heated.

- Magnetocaloric alloys (LaFeSi) enable energy-efficient refrigeration.

| Alloy Type | Primary Components | Key Properties | Applications |

|---|---|---|---|

| Steel | Iron (Fe) + Carbon (C) | High strength, machinable | Construction, automotive |

| Stainless Steel | Fe + Chromium (Cr) + Nickel (Ni) | Corrosion-resistant | Medical tools, kitchenware |

| Brass | Copper (Cu) + Zinc (Zn) | Malleable, acoustic properties | Musical instruments, plumbing |

| Bronze | Cu + Tin (Sn) | Wear-resistant, durable | Bearings, sculptures |

| Aluminum Alloys | Al + Magnesium (Mg)/Silicon (Si) | Lightweight, strong | Aircraft, packaging |

| Titanium Alloys | Ti + Aluminum (Al)/Vanadium (V) | High strength-to-weight ratio | Aerospace, medical implants |

In Conclusion

Alloys are essential in modern engineering because they combine the best properties of different metals while minimizing weaknesses. From construction (steel) to aerospace (titanium alloys), they enable stronger, lighter, and more durable materials than pure metals alone.

Key Takeaway:

🔹 Alloys = Metal + Other Elements (for better performance)

🔹 Used in almost every industry (automotive, electronics, medicine, etc.)

🔹 Offer superior strength, corrosion resistance, and workability compared to pure metals.