Duplex stainless steels (DSS) are a family of high-performance alloys combining the best properties of austenitic and ferritic stainless steels. With a dual-phase microstructure (typically ~50% ferrite, 50% austenite), they offer:

✔ Exceptional strength (2x stronger than standard austenitics)

✔ Superior stress corrosion cracking resistance

✔ Excellent toughness and weldability

✔ Good cost-performance ratio

This technical dossier provides an in-depth analysis of duplex stainless steels, covering:

Chemical compositions of key grades

Mechanical & physical properties (with comparative data)

Advantages over conventional stainless steels

Industrial applications & cost analysis

Performance in extreme environments

| Grade | *PREN (Cr+3.3Mo+16N)** | Key Applications |

|---|---|---|

| Lean Duplex (e.g., 2304) | 24-26 | Structural, tanks, bridges |

| Standard Duplex (e.g., 2205) | 35-38 | Oil & gas, chemical processing |

| Super Duplex (e.g., 2507) | 40-45 | Offshore, seawater systems |

| Hyper Duplex (e.g., 2707 HD) | >45 | Extreme chloride environments |

Microstructural Fundamentals of Duplex Stainless Steel

Chemical Composition of Duplex Stainless Steel

| Element | 2304 (S32304) | 2205 (S32205) | 2507 (S32750) | Zeron 100 (S32760) |

|---|---|---|---|---|

| Cr | 21.5-24.5 | 22.0-23.0 | 24.0-26.0 | 24.0-26.0 |

| Ni | 3.0-5.5 | 4.5-6.5 | 6.0-8.0 | 6.0-8.0 |

| Mo | 0.05-0.6 | 3.0-3.5 | 3.0-4.0 | 3.0-4.0 |

| N | 0.05-0.20 | 0.14-0.20 | 0.24-0.32 | 0.20-0.30 |

| Cu | – | – | – | 0.5-1.0 |

| W | – | – | – | 0.5-1.0 |

Physical Properties of Duplex Staninless Steel

| Property | 2205 | 2507 | 316L |

|---|---|---|---|

| Density (g/cm³) | 7.80 | 7.80 | 7.99 |

| Thermal Conductivity (W/m·K) | 19 | 15 | 16 |

| CTE (10^-6/K, 20-100°C) | 13.0 | 12.5 | 16.0 |

| Electrical Resistivity (μΩ·cm) | 85 | 90 | 74 |

Mechanical Properties of Staninless Steel

| Property | 2304 | 2205 | 2507 | 316L (for comparison) |

|---|---|---|---|---|

| Tensile (MPa) | 600-750 | 620-795 | 800-1000 | 485-620 |

| Yield (MPa) | 400-550 | 450-550 | 550-750 | 170-310 |

| Elongation (%) | 25-30 | 25-30 | 15-25 | 40-50 |

| Hardness (HV) | 220-280 | 250-290 | 290-350 | 150-220 |

| Impact (J, -40°C) | >100 | >100 | >80 | >100 |

Duplex stainless steels (DSS) offer a unique combination of properties that make them highly advantageous for various industrial applications. Their microstructure, consisting of roughly equal proportions of austenite and ferrite phases, imparts exceptional strength and corrosion resistance.

Key Advantages of Stainless Steel

One of the key advantages of DSS is their high yield strength, typically twice that of standard austenitic stainless steels. This allows for the use of thinner sections, reducing material costs and weight in structures. Additionally, DSS exhibits excellent resistance to stress corrosion cracking (SCC), particularly in chloride-containing environments, making them ideal for marine and offshore applications.

DSS also demonstrate superior resistance to pitting and crevice corrosion, attributed to their high chromium, molybdenum, and nitrogen content. This makes them suitable for aggressive chemical environments and seawater applications. Furthermore, their good weldability and toughness, even at low temperatures, enhance their versatility in manufacturing processes.

Despite their higher initial cost compared to some stainless steels, the long-term benefits of DSS, such as reduced maintenance and extended service life, often result in cost savings. Their balanced properties position DSS as a preferred choice in industries demanding durability, strength, and corrosion resistance, including oil and gas, chemical processing, and infrastructure.

Applications of Stainless Steel

| Industry | Applications | Preferred Grades |

|---|---|---|

| Oil & Gas | Subsea pipelines, X-mas trees | 2205, 2507 |

| Chemical | Reactors, heat exchangers | 2205, Zeron 100 |

| Desalination | RO membranes, brine heaters | 2507, 2707 HD |

| Pulp & Paper | Digesters, bleach plants | 2205, 2304 |

| Architecture | Bridges, coastal structures | 2304, 2205 |

Manufacturing Costs and Processing Considerations

✔ Excellent resistance to chloride-induced stress corrosion cracking (SCC)

Performs better than 316L in seawater and chloride-rich environments.

✔ High pitting & crevice corrosion resistance (due to high PREN values)*PREN (Pitting Resistance Equivalent Number) = Cr + 3.3Mo + 16N*

2205 (PREN ~35-38) vs. 316L (PREN ~24-26)

✔ Resistant to general corrosion in acids, alkalis, and oxidizing environments

✔ Wide range of grades for different environments:

Lean Duplex (2304) – Cost-effective alternative to 316L

Standard Duplex (2205) – Most widely used (oil & gas, chemical)

Super Duplex (2507, Zeron 100) – Extreme chloride resistance

Hyper Duplex (2707 HD) – For ultra-harsh conditions

| Material | Base Cost | Fabrication Cost | Lifetime Cost |

|---|---|---|---|

| 2304 | $4.5-6.0 | Moderate | Low |

| 2205 | $6.0-8.0 | Moderate | Medium |

| 2507 | $9.0-12.0 | High | Medium-High |

| 316L | $5.0-7.0 | Low | High (in chloride) |

In Conclusion

Duplex stainless steels provide the optimal balance between:

✓ Cost-efficiency (lower Ni/Mo than super austenitics)

✓ Performance (strength + corrosion resistance)

✓ Sustainability (long service life reduces replacements)

Selection Guidelines:

2304: Cost-sensitive structural applications

2205: Most versatile (90% of duplex market)

2507/Zeron 100: Extreme chloride/acid environments

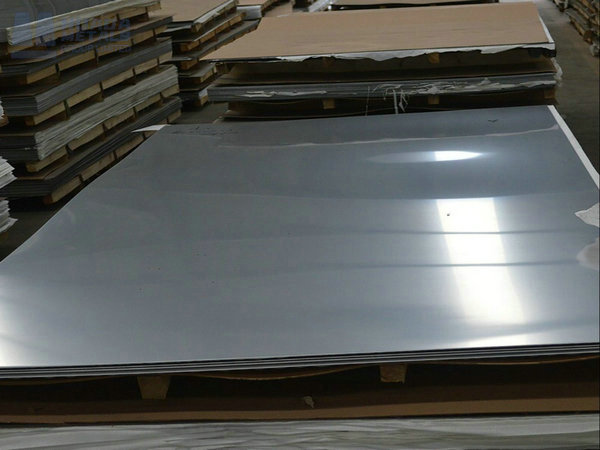

HuaDa Metals has the good quality products and contact us.